ZLTECH Nema23 closed loop integrated step motor for CNC

Outline

ZLIS42 is a 2 phase hybrid step-servo motor with high-performance digital integrated drive. The system has a simple structure and high integration. This series of integrated closed-loop stepper motors use the latest 32-bit dedicated DSP chip for motor control, and use advanced digital filter control technology, resonance vibration suppression technology and precise current control technology to enable the two-phase hybrid stepper motor to achieve precise and stable operation . This series of integrated closed-loop stepper motors have the characteristics of large torque output, low noise, low vibration, and low heat, which are especially suitable for electronic processing equipment, laser processing, medical and small numerical control equipment.

Features

1.Full closed loop control, no step loss;

2.Low vibration and noise;

3.Maximum 512 microstep subdivision, minimum unit 2;

4.Input voltage:18V-36VDC;

5.3 isolated differential signal input ports: 3.3-24VDC;

6.1 isolated output port: alarm output, OC;

7.The current control is smooth and accurate, and the motor has low heat generation;

8.4 DIP switch selection, 16-segment step resolution;

9.With over-voltage, over-current, out of tolerance protect function etc;

10.With built-in 1000-wire magnetic encoder, provides real-time feedback of motor running state.

Advantage

Small volume, high cost performance, low failure rate, without matching motor and drive controller, a variety of control mode (optional) pulse and CAN bus, simple to use, system design and maintenance is convenient, big | to reduce product development time.

Stepper motor can transform electrical pulse signal into angular or linear displacement. In the rated power range, the speed of the motor only depends on the frequency and pulse number of the pulse signal, and is not affected by the load change, coupled with the characteristics of small cumulative error of the stepper motor, which makes it easier to control the speed, position and other fields with the stepper motor. Stepper motor is divided into three kinds, the hybrid stepper motor is widely used at present.

Parameters

| Item | ZLIS42-05 | ZLIS42-07 |

| Shaft | Single shaft | Single shaft |

| Size | Nema17 | Nema17 |

| step angle | 1.8° | 1.8° |

| Input voltage(VDC) | 18-36 | 18-36 |

| Output current peak(A) | 1.2 | 1.2 |

| Step signal frequency(Hz) | 200k | 200k |

| Control signal input current(mA) | 10 | 10 |

| Over-voltage protection(VDC) | 29 | 29 |

| Input signal voltage(VDC) | 5 | 5 |

| shaft diameter(mm) | 5/8 | 5/8 |

| shaft length(mm) | 24 | 24 |

| Holding Torque(N.m) | 0.5 | 0.7 |

| Speed(RPM) | 2500 | 2500 |

| Encoder | 2500-wire Magnetic | 2500-wire Magnetic |

| Insulation resistance(MΩ) | 100 | 100 |

| Service temperature(℃) | 0~50 | 0~50 |

| Max. ambient humidity | 90% RH | 90% RH |

| Storage temperature(℃) | -10~70 | -10~70 |

| Vibration | 10~55Hz/0.15mm | 10~55Hz/0.15mm |

| Weight(g) | 430 | 430 |

| Motor Length(mm) | 70 | 82 |

| Motor total Length(mm) | 94 | 106 |

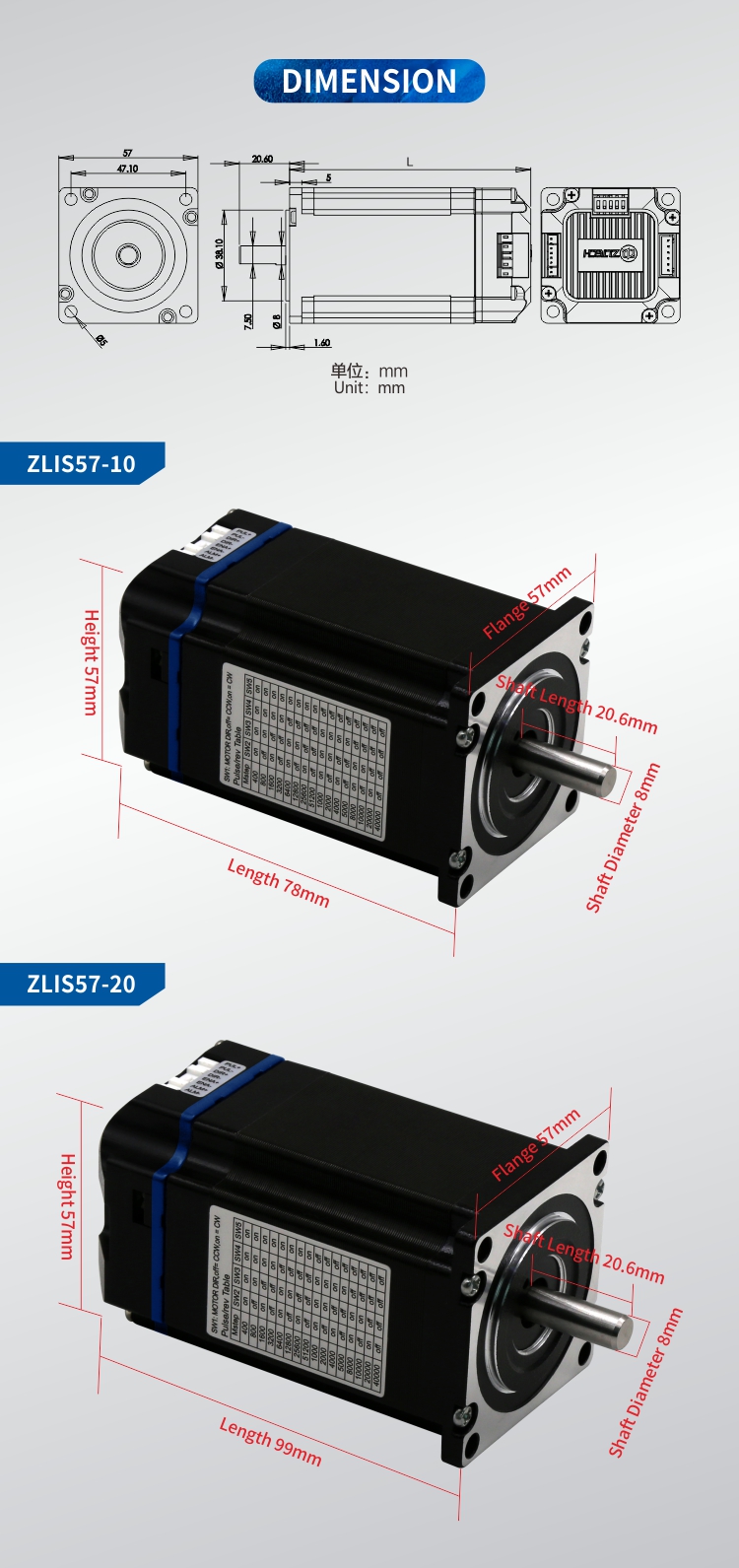

Dimension

Application

Packing

Production & Inspection Device

Qualification & Certification

Office & Factory

Cooperation