ZLTECH 2 phase Nema34 4.5N.m 24V dc step motor with 1000-wire for CNC machine

Features

1. Closed loop control technology, like AC servo system, does not lose step. The position encoder is installed to make the motor have the closed-loop characteristics of the servo motor, which fundamentally solves the problem of step loss of the traditional stepper motor.

2. High speed performance of large lifting motor. The effective torque of the motor can be increased by more than 30%.

3. Effectively reduce the heat of the motor. The output current of the driver increases with the increase of load and speed, and decreases with the decrease.

4. Shorten the corresponding time of motor acceleration and deceleration. The output and input commands of the position response are almost synchronized in real time, so it is very suitable for short distance fast start stop and zero speed steady stop The motor does not vibrate when braking. The closed-loop stepper servo driver system has the unique torque holding characteristics of the stepper motor, which can reach the set position stably and avoid oscillation.

5. The closed-loop stepper motor runs more smoothly and has higher accuracy. The most advanced special motor control DSP chip is adopted, and the technology of vector control and smooth filtering is applied to realize the smooth motion control of the stepper motor.

6. It is very convenient to use without gain adjustment. The closed-loop stepper servo system has the dual advantages of the convenience of stepping motor and the reliability of servo system, which can be used easily without tedious parameter debugging.

FAQ

1.Q:Are you factory?

A:Yes.

2.Q: How to select the motor model?

A: Before purchasing,please contact us to confirm the model no and specification to avoid any misunderstanding.

3.Q: What’s your warranty?

A:Our warranty is 12 months from shipment out of factory.

4.Q:What is your payment way?

A: Sample cost should be fully paid before production. For bulk order, you can discuss with ZLTECH.

5.Q:How can we know the product quality?

A: ZLTECH suggest you to order a sample. Also, you can send ZLTECH email for detail photos for checking if you cannot get enough information in the product page.

Parameters

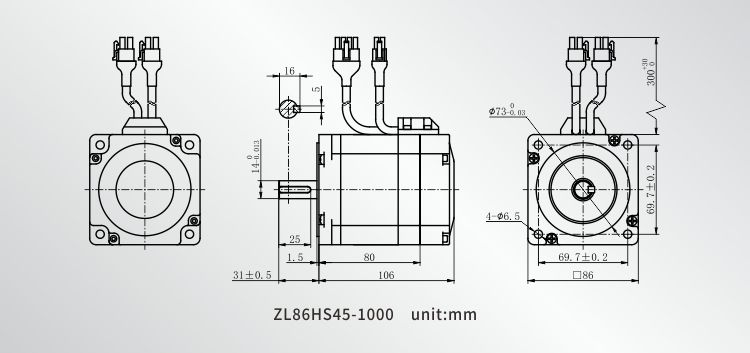

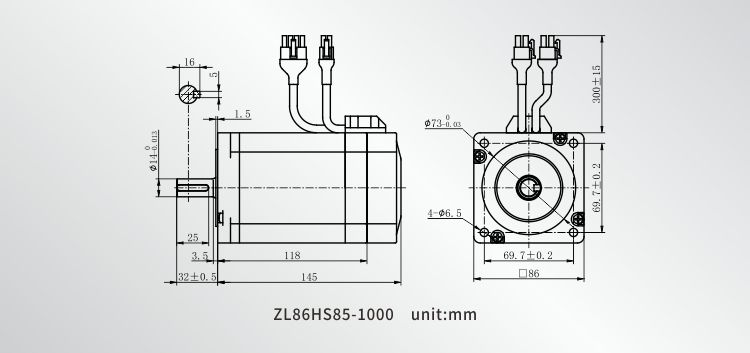

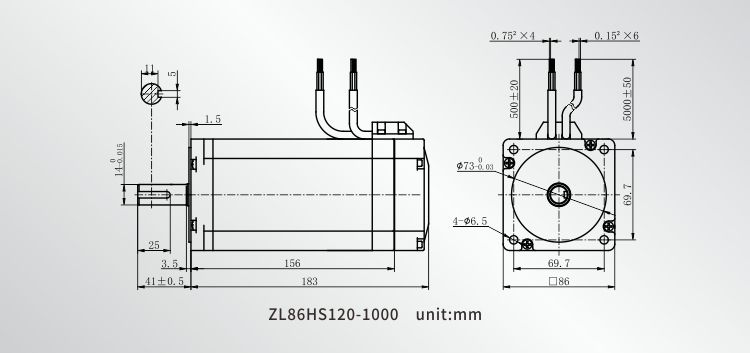

| Closed loop motor | ZL86HS45-1000 | ZL86HS85-1000 | ZL86HS120-1000 |

| Size | Nema34 | Nema34 | Nema34 |

| step angle | 1.8° | 1.8° | 1.8° |

| Positional Accuracy(no load) | ±0.09° Max | ±0.09° Max | ±0.09° Max |

| shaft diameter(mm) | 14 | 14 | 14 |

| shaft extension(mm) | Flat key(5*5*25) | Flat key(5*5*25) | Flat key(5*5*25) |

| shaft length(mm) | 31 | 32 | 41 |

| Rated Torque(N.m) | 4.5 | 8.5 | 12.2 |

| Phase Current(A) | 6 | 6 | 6 |

| Phase Resistance(Ω) | 0.41 | 0.49 | 0.76 |

| Phase Inductance(mH) | 2.9 | 4 | 8.4 |

| Rotor Inertia(g.cm) | 1400 | 2700 | 4000 |

| Encoder | 1000-wire Optical | 1000-wire Optical | 1000-wire Optical |

| Weight(kg) | 2.8 | 3.8 | 4.5 |

| Motor Length(mm) | 106 | 145 | 183 |

Dimension

Application

Brushless DC motors are widely used in electronic manufacturing, medical equipment, packaging equipment, logistics equipment, industrial robots, photovoltaic equipment and other automation fields.

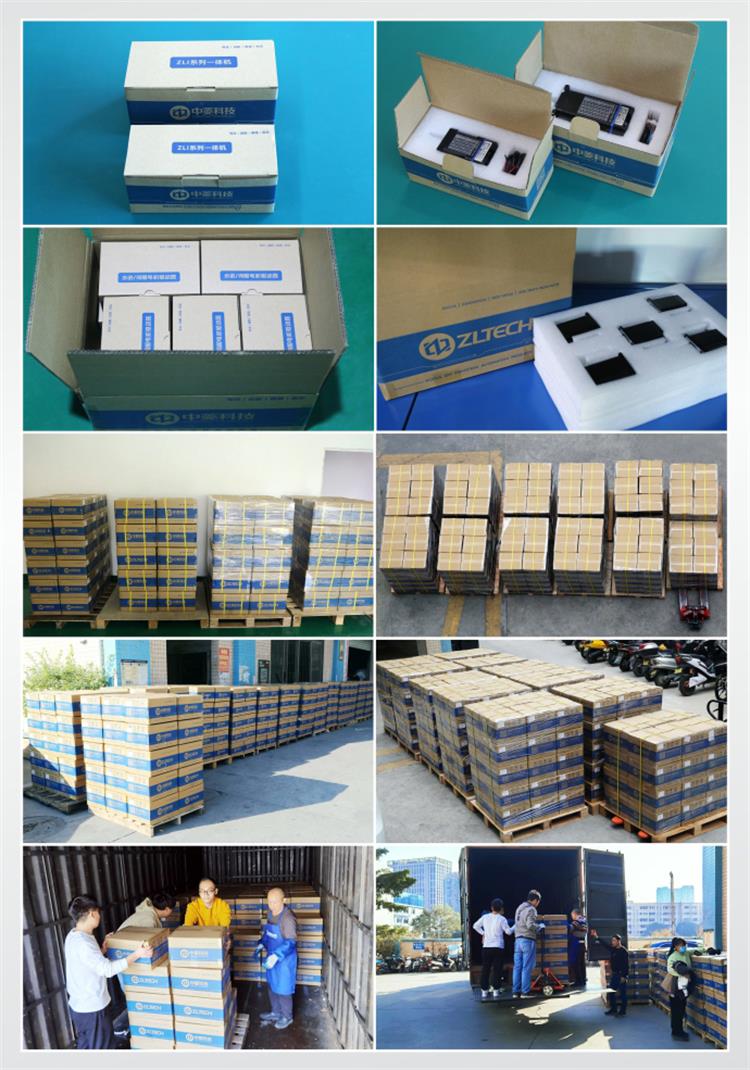

Packing

Production & Inspection Device

Qualification & Certification

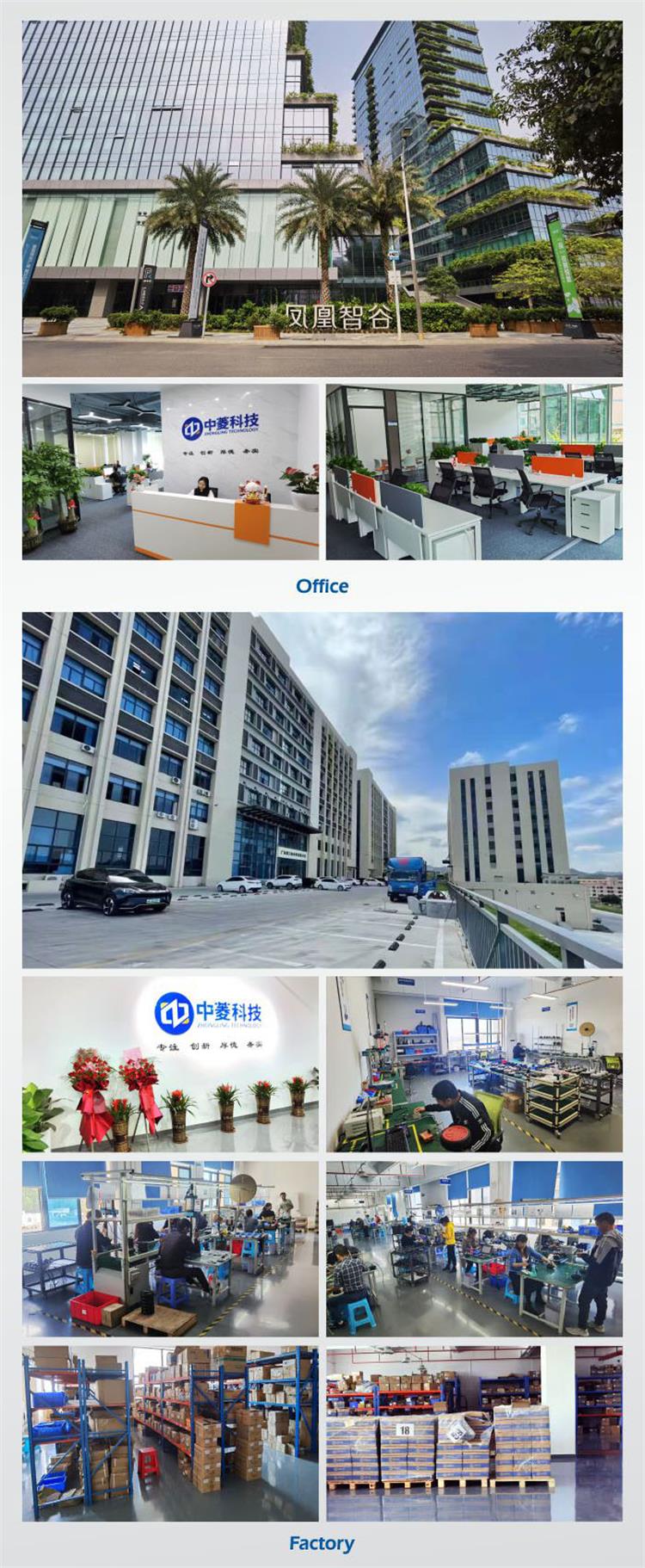

Office & Factory

Cooperation