ZLTECH 3phase 110mm Nema42 48V DC 1000W 27A 3000RPM brushless motor for robotic arm

Brushless DC motors are common in industrial applications across the world. At the most basic level, there are brushed and brushless motors and there are DC and AC motors. Brushless DC motors don't contain brushes and use a DC current.

These motors provide many specific advantages over other types of electrical motors, but, going beyond the basics, what exactly is a brushless DC motor? How does it work and what’s it used for?

How a Brushless DC Motor Works

It often helps to explain how a brushed DC motor works first, as they were used for some time before brushless DC motors were available. A brushed DC motor has permanent magnets on the outside of its structure, with a spinning armature on the inside. The permanent magnets, which are stationary on the outside, are called the stator. The armature, which rotates and contains an electromagnet, is called the rotor.

In a brushed DC motor, the rotor spins 180-degrees when an electric current is run to the armature. To go any further, the poles of the electromagnet must flip. The brushes, as the rotor spins, make contact with the stator, flipping the magnetic field and allowing the rotor to spin a full 360-degrees.

A brushless DC motor is essentially flipped inside out, eliminating the need for brushes to flip the electromagnetic field. In brushless DC motors, the permanent magnets are on the rotor, and the electromagnets are on the stator. A computer then charges the electromagnets in the stator to rotate the rotor a full 360-degrees.

What are Brushless DC Motors Used For?

Brushless DC motors typically have an efficiency of 85-90%, while brushed motors are usually only 75-80% efficient. Brushes eventually wear out, sometimes causing dangerous sparking, limiting the lifespan of a brushed motor. Brushless DC motors are quiet, lighter and have much longer lifespans. Because computers control the electrical current, brushless DC motors can achieve much more precise motion control.

Because of all these advantages, brushless DC motors are often used in modern devices where low noise and low heat are required, especially in devices that run continuously. This may include washing machines, air conditioners and other consumer electronics.

Parameters

| Item | ZL110DBL1000 |

| Phase | 3 Phase |

| Size | Nema42 |

| Voltage (V) | 48 |

| Rated Power (W) | 1000 |

| Rated Current (A) | 27 |

| Peak Current (A) | 81 |

| Rated Torque (N.m) | 3.3 |

| Peak Torque (N.m) | 10 |

| Rated Speed (RPM) | 3000 |

| No. of Poles (Pairs) | 4 |

| Resistance (Ω) | 0.07±10% |

| Inductance (mH) | 0.30±20% |

| Ke (RMS)(V/RPM) | 8.4x10-3 |

| Rotor Inertia (kg.cm²) | 3 |

| Torque Coefficient (N.m/A) | 0.125 |

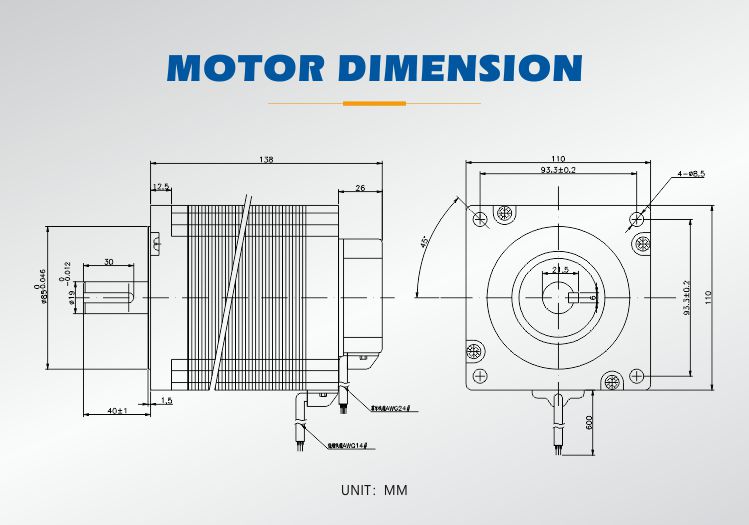

| Shaft Diameter (mm) | 19 |

| Shaft Length (mm) | 40 |

| Motor Length (mm) | 138 |

| Weight (kg) | 4.5 |

| Adapted BLDC Driver | ZLDBL5030S |

Dimension

Application

Packing

Production & Inspection Device

Qualification & Certification

Office & Factory

Cooperation