Bottom price 10inch Wheel Chair Brushless Motor - ZLTECH 160mm 400kg load 16~70 ratio gear wheel – ZhongLing

Bottom price 10inch Wheel Chair Brushless Motor - ZLTECH 160mm 400kg load 16~70 ratio gear wheel – ZhongLing Detail:

Advantages

In the process of handling, in order to ensure that the AGV can successfully complete the handling task, in the wheel edge drive deceleration, steering, jacking or repetitive action to achieve a foolproof, manufacturers often use reducer to ensure the positioning accuracy and repeated positioning accuracy of AGV. And, in addition to maintaining accuracy, the gear can increase the output torque without changing the power of the servo motor, thus increasing the traction capacity of the AGV.

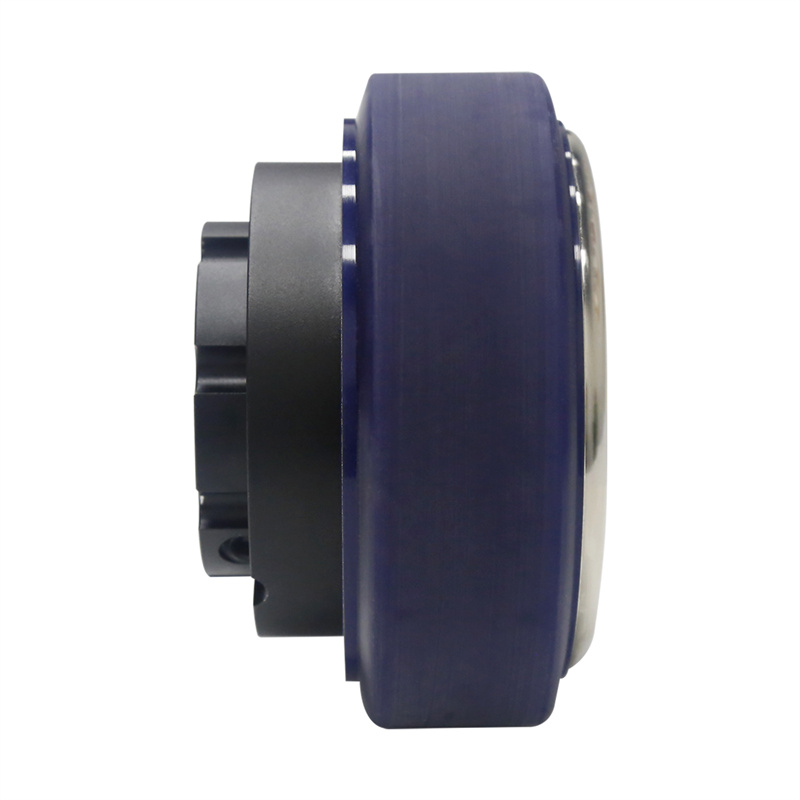

This reducer wheel has the characteristics of quiet, high efficiency and so on, but also has the advantages of small return difference and high precision, so it is more convenient to carry AGV trajectory control in the operation. In addition, the output rotation mode of this product is shell rotation, not easy to loose, and increase the rotational stability and bearing capacity. More importantly, the matching of the reducer wheel is very strong, and the servo motor or other suitable rotary power source can achieve perfect cooperation.

Parameters

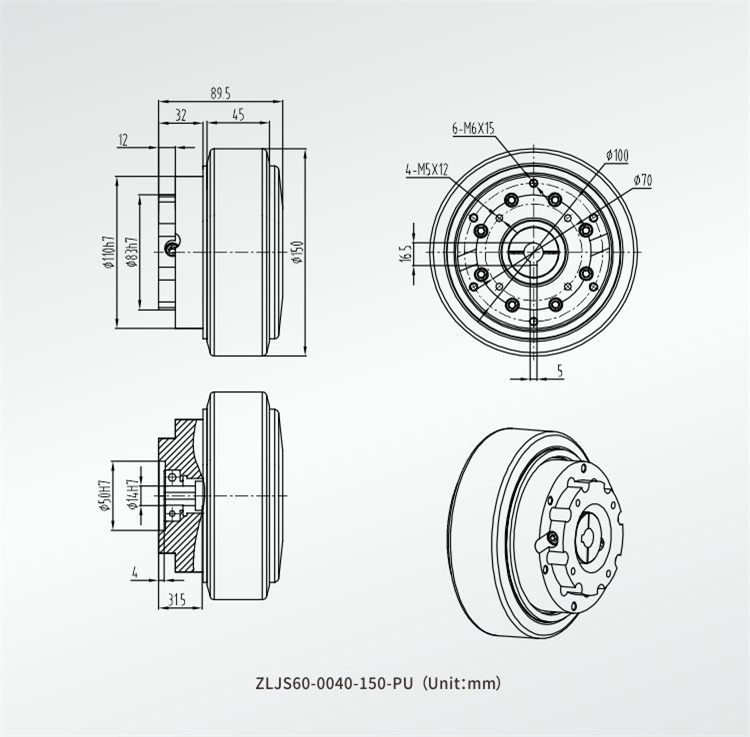

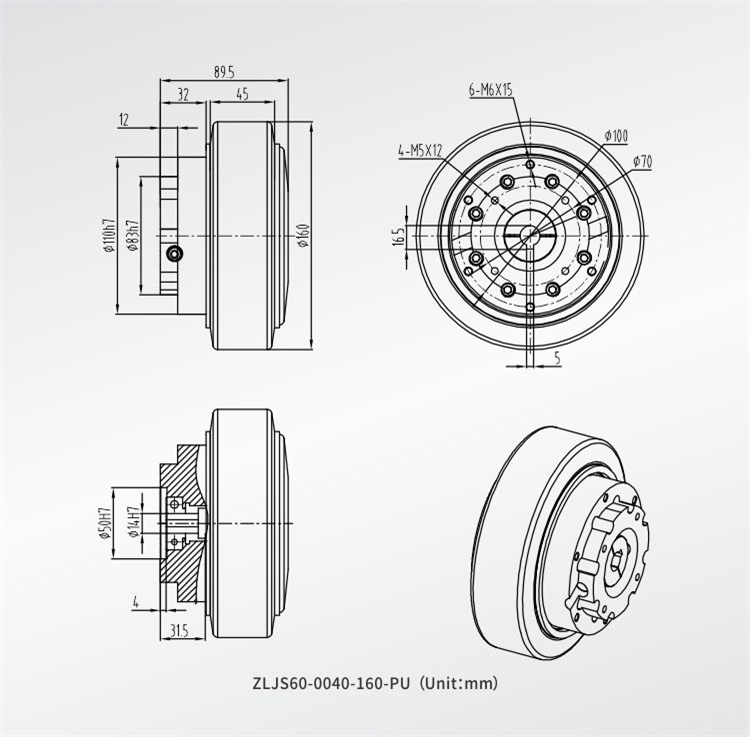

| Reduction wheel model | ZLLS60-0040-150-PU | ZLLS60-0040-160-PU |

| Reducer speed ratio(i) | 16/20/25 | 16/20/25 |

| Reducer torque(Nm) | 30/33/33 | 30/33/33 |

| Polyurethane load-bearing(Kg) | 400 | 400 |

| hardness(A) | 90±5 | 90±5 |

| Maximum speed(M/min) | 88.3/70.7/56.5 | 94.2/75.4/60.3 |

| traction(N) | 243.8/304.8/381.0 | 228.6/285.8/357.2 |

| towing weight(Kg)reference | 463.3/579.1/723.9 | 434.3/542.9/678.7 |

| weight(Kg) | 5 | 5 |

Dimension

Application

Brushless DC motors are widely used in electronic manufacturing, medical equipment, packaging equipment, logistics equipment, industrial robots, photovoltaic equipment and other automation fields.

Packing

Production & Inspection Device

Qualification & Certification

Office & Factory

Cooperation

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Bottom price 10inch Wheel Chair Brushless Motor - ZLTECH 160mm 400kg load 16~70 ratio gear wheel – ZhongLing , The product will supply to all over the world, such as: Irish, Georgia, Johor, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!