In the current era of rapid development in the automation and intelligent equipment industry, Shenzhen Zhongling Technology Co., Ltd (ZLTECH for short) is like a shining star, standing out in the fierce market competition with its profound technological accumulation and innovative strength. The outer-rotor hub servo motor launched by ZLTECH has attracted much attention in the industry for its excellent performance. Among them, although the performance of single shaft outer-rotor hub servo motor and double shaft outer-rotor hub servo motor are similar, there are significant differences in installation, just like two pearls with different styles, providing precise adaptation solutions for different application scenarios such as AGV.

1. Single shaft outer-rotor hub servo motor: simple installation, efficient adaptation to AGV

The installation process of the single shaft outer-rotor hub servo motor is simple and efficient. From the perspective of space occupation, the single shaft design results in only one power output shaft, making the overall structure compact. This characteristic is fully demonstrated in space sensitive AGV.

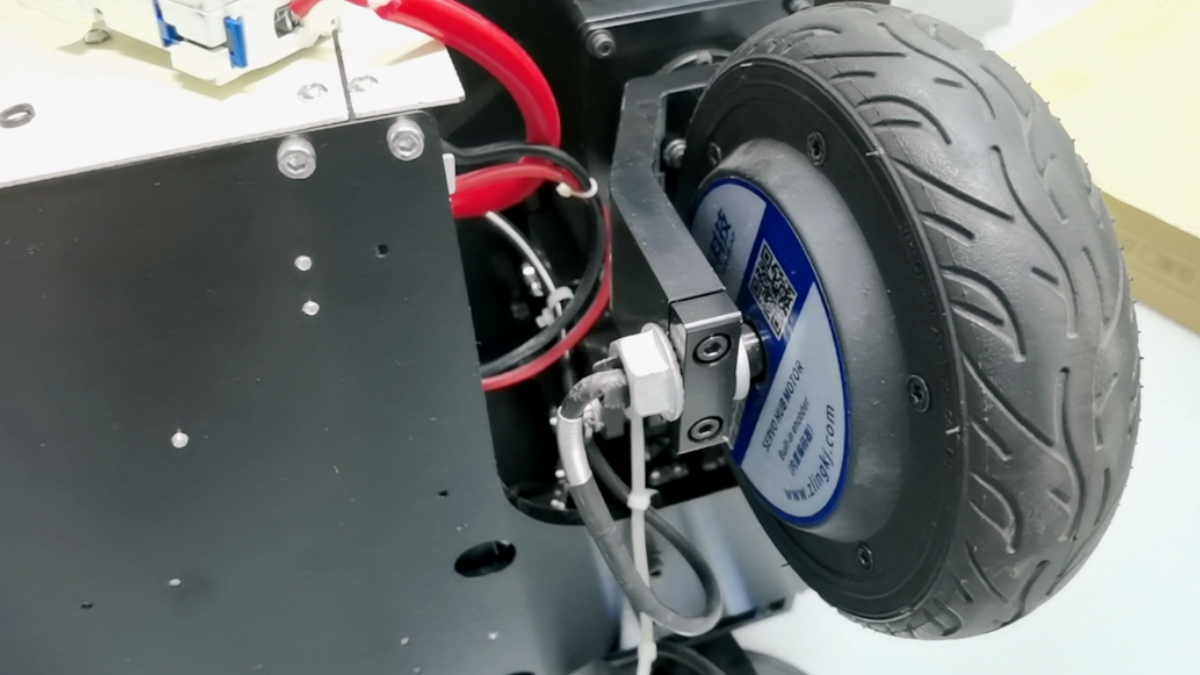

The interior space of AGV is precious and needs to accommodate numerous key components such as batteries, control systems, sensors, etc. Single shaft motor, with its compact structure, can be easily installed at the bottom or in narrow positions of AGV without taking up too much internal space. For example, in compact AGV, the single shaft motor can be cleverly embedded in the bottom wheel hub, leaving ample room for the reasonable layout of navigation modules, communication equipment, and other components, ensuring that the AGV structure is compact, stable in operation, and can flexibly shuttle in narrow passages or complex environments.

In terms of installation, the interface design of the single shaft motor is simple and adopts standardized connection methods. Whether it is bolted or snap on installation, it can be quickly completed, greatly reducing the installation and debugging time of AGV and improving production efficiency. And its structure is single, with a low probability of installation failure, reducing installation costs and later maintenance difficulties.

2. Double shaft outer-rotor hub servo motor: Multi element installation, precise driving AGV

Unlike single shaft motor, double shaft outer-rotor hub servo motor has more diversity and precision in installation. The double shaft structure endows the motor with the ability to output power in two directions simultaneously, bringing new possibilities for complex AGV applications and placing higher demands on installation accuracy.

In some special function AGV applications, if complex actions such as forward, backward, and steering need to be achieved simultaneously, or multiple auxiliary components need to work together, double shaft motor can meet the requirements. It needs to be precisely docked with the AGV drive wheels or related components, which requires installation personnel to have higher technical level and fine operation ability to ensure the installation accuracy and coaxiality of the two output shafts, ensuring smooth and accurate operation of the AGV. Like omnidirectional mobile AGVs, double shaft motor control wheels in different directions to achieve arbitrary movement in a plane. Accurate installation is the key to the coordinated work of each wheel.

Although the double shaft motor occupies a large space, it can achieve more complex power distribution and driving methods. Through careful installation, design, and debugging, its potential can be fully realized to meet the high-precision driving requirements of complex AGV application scenarios.

ZLTECH single shaft and double shaft outer-rotor hub servo motors have their own advantages in installation. Single shaft motor is simple and efficient, suitable for AGV scenarios with limited space and simple installation. Double shaft motor plays a crucial role in complex AGV applications and high-precision driving requirements due to its multiple precision elements. They embody ZLTECH persistent pursuit of product quality and technological innovation, injecting strong impetus into the development of automation fields such as AGV, promoting the widespread application and continuous upgrading of AGV in logistics, warehousing, manufacturing and other industries, and helping the industry move towards a new era of intelligence.

Post time: Jun-04-2025