In the application of hub motor in robot (especially AGV/AMR, service robot, mobile robots, etc.), the electromagnetic brake that can be manually released is an extremely critical and multifunctional component. Its function goes far beyond the ordinary “parking brake” and is deeply integrated into the entire process of robot safety, control, and operation.

In the field of robot, electromagnetic brake that can be manually released are not only safety devices, but also the core link of system control, safety assurance, and maintenance convenience. The main functions can be summarized as follows:

1. Safety locking and emergency braking

Robot works in dynamic and potentially collaborative environments, with safety being the top priority.

1) Emergency stop: When the safety LiDAR, emergency stop button, and collision sensor are triggered, the controller immediately cuts off the power supply to the wheel hub motor. Electromagnetic braking instantly locks in place, achieving millisecond level response and stopping the robot in place to prevent secondary injury.

2) Fault safety: In case of any abnormal power outage such as control system shutdown, communication interruption, power failure, etc., the brake will be automatically triggered to prevent the robot from sliding due to its own weight or inertia.

3) Slope parking: When working on warehouse slopes or uneven ground, ensure that the parking state is absolutely stable and does not slip.

2. Precise parking and position maintenance (core performance requirement)

Robot operations (such as loading, unloading, docking, and assembly) require extremely high precision for repeated positioning of the end effector.

1) Zero position maintenance: After reaching the target point, the brake is locked to eliminate any small creep or reverse clearance of the motor and transmission chain, ensuring that the positioning accuracy is not affected by external forces.

2) Energy saving and stable: Compared to servo motors that are continuously powered on for “zero speed clamping” to maintain position, after the electromagnetic brake is locked, the motor driver can be completely powered off, achieving zero power consumption and precise maintenance, while avoiding motor heating.

3. Enable collaboration and maintenance mode (key human-computer interaction functions)

This is where the value of the manual brake release function is maximized.

1) Manual guidance teaching: When debugging or replanning the path, the operator can manually release the brake to easily push and pull the robot to a new position for point-to-point teaching. After completion, the system will power on and the brakes will automatically resume.

2) Safe dragging: When the robot is stuck in a narrow space or needs to be temporarily moved, manual release of the brake is the only safe way to move.

3) Maintenance and Overhaul: Convenient for technicians to perform rotation inspection, replacement of parts, and other operations on wheel systems and motors.

4) Power off recycling: In the event of battery depletion or severe malfunction, the robot can be pushed back to the charging station or maintenance area.

4. Energy conservation and thermal management

1) Static zero power consumption: When the robot is waiting for a task or parked for a long time, the driver can be turned off, and only the mechanical brake can maintain its position, greatly saving system energy consumption and extending battery life.

2) Reduce heat load: avoids the heat generated by long-term high current stalling of servo motors, improves system reliability, especially suitable for storagerobots with high duty cycle operations.

Compared with other robot braking solutions, the electromagnetic brake that can be manually released has the advantages of fault safety, zero power consumption maintenance, manual dragging, and fast response. At the same time, it also has high cost, complex structure, and mechanical wear and tear, and is suitable for the vast majority of mobile robots that require dragging, especially AGVs, heavy-duty robots, collaborative mobile platforms, etc.

The selection and design of electromagnetic brakes that can be manually released mainly consider the following factors:

1. Maintain torque: It must be greater than the maximum self weight of the robot and the sliding force generated by the load on the maximum slope, and have sufficient safety margin (usually ≥ 1.5 times).

2. Response time: The time from power outage to full torque output affects safety performance, and the shorter the better.

3. Manual release method: release force (should be easy for manual operation), release stroke, and whether there is a release status indicator.

4. Environmental adaptability: IP protection level (dustproof and waterproof), working temperature range, and anti vibration ability.

5. Electrical interface: voltage level (usually 24VDC), power consumption, whether there is a status feedback signal (such as “released/tightened” switch).

For robot hub motor, electromagnetic brakes that can be manually released have evolved from an optional accessory to a system level safety and functional core. It establishes a physical security baseline, achieves the unity of high precision and high efficiency, and connects the critical path of human-machine collaboration. Its value lies in the deep integration of safety, functionality, and maintainability, making it an indispensable intelligent execution mechanism for ensuring the reliable, flexible, and safe operation of robots.

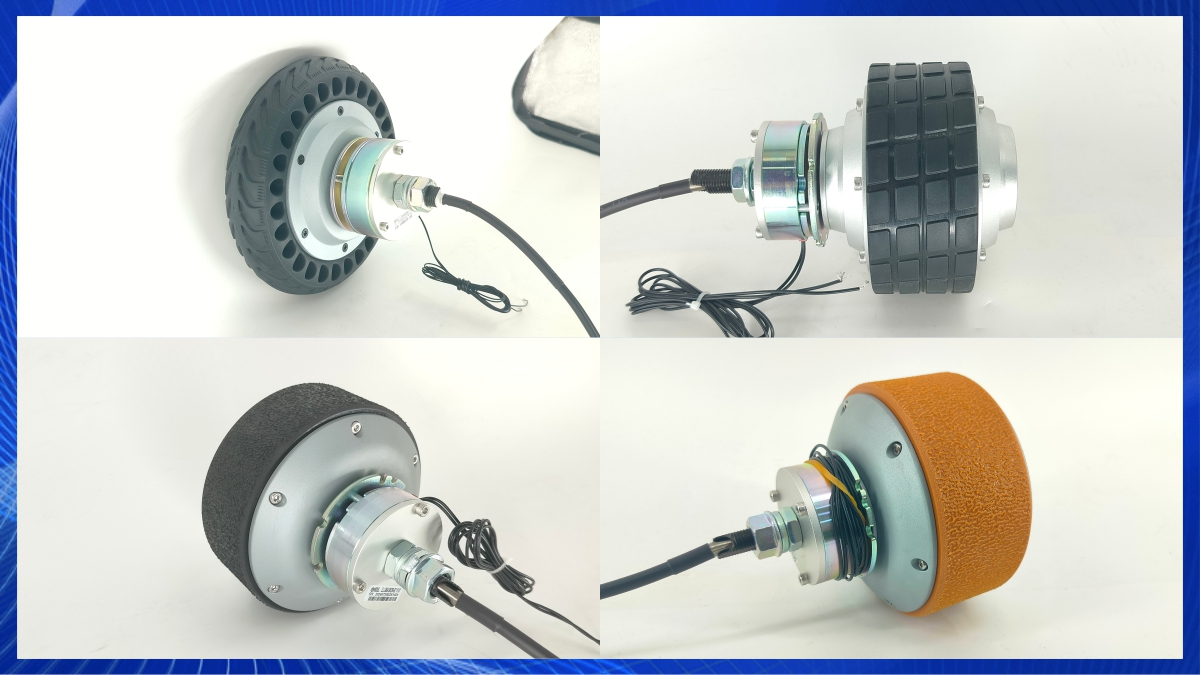

Shenzhen Zhongling Technology Co., Ltd (www.zlingkj.com), is a high-tech company that integrates research and development, production, and sales of wheel hub servo motors and drives. It is committed to providing products and customized solutions for industries such as AGV and intelligent logistics robots. For applications with high safety requirements, Zhongling Technology Co., Ltd, can provide hub servo motors and various torque and functional electromagnetic brake solutions to meet customer requirements. With the trend of intelligent logistics approaching, the development prospects of intelligent logistics robots can be described as very broad. As a supplier of essential underlying motion components in intelligent logistics systems – hub servo motors, Shenzhen Zhongling Technology Co., Ltd, will continue to optimize product design and production processes, continuously improve product materials and performance, and inject new development momentum into the unmanned and intelligent logistics industry!

Post time: Dec-24-2025