In the world of infinite possibilities for robots, every seemingly ordinary “walk” hides a silent competition with complex environments. Let’s imagine: a delivery robot with a mission, is rolling over slippery puddles after rain without hesitation; A AGV car is shuttling through a smart factory, precisely navigating through the air where metal debris and dust intertwine; Or it could be an outdoor inspection robot, is facing sandstorms and drizzle, steadfastly moving forward in the dawn or dusk.

The core secret of these robots’ ability to remain so ‘unfazed’ and fearless of gravel and water stains is not just their advanced algorithms or cool appearance. What truly provides all-weather protection for their “feet” – wheel hub motor – is a set of precision invisible armor called “IP level”.

IP level: Decrypt password for “Armor”

You may have seen the word “IPXX” in many electrical parameters. This is not a mysterious code, but an international standard developed by the International Electrotechnical Commission (IEC) to clearly define the product’s ability to protect against the intrusion of solid foreign objects (including dust) and liquids (mainly water).

The first digit (dust level) ranges from 0 to 6. The larger the number, the stronger the protection. For robot wheel hub motors that often work on complex surfaces, IP6X represents “completely dust-proof”, ensuring that no fine dust can enter the interior and guaranteeing absolute cleanliness of core precision components.

Second digit (waterproof level) ranges from 0 to 8. This is the key to dealing with dampness, splashing water, and even short-term immersion. For example, IPX4 is splash proof, while IPX7 allows for short-term immersion in 1 meter deep water. This means that whether it is unexpected rainwater, ground flushing water, or accidental small puddles, they cannot cause disturbance to the motor.

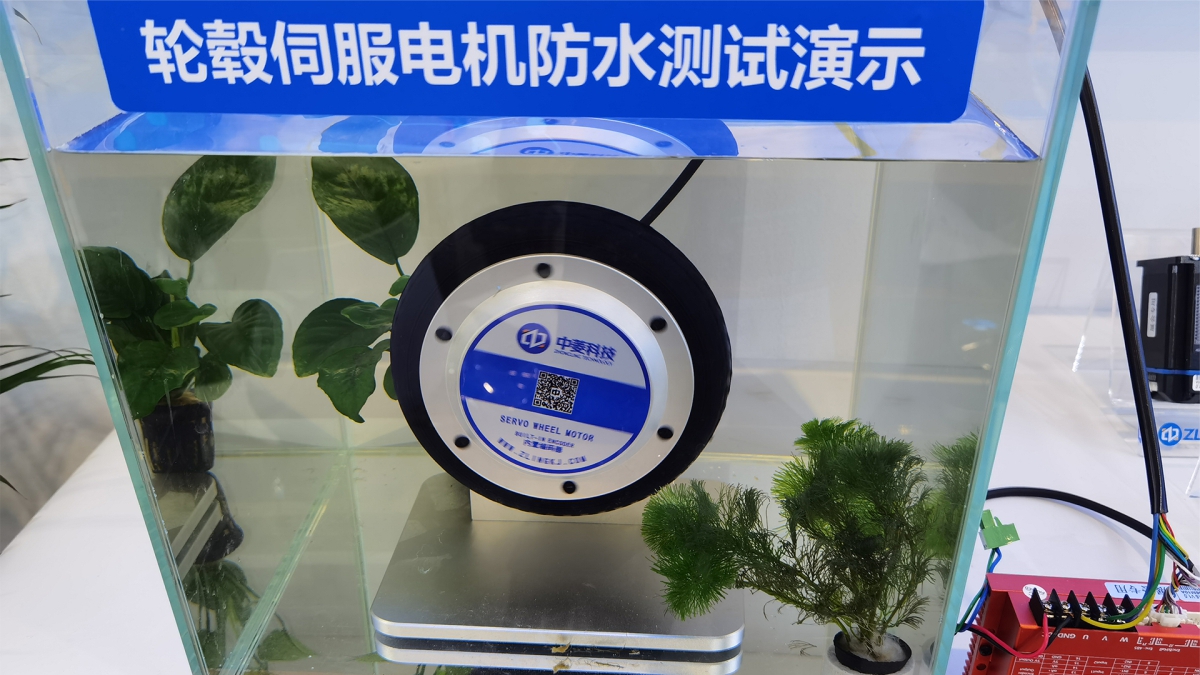

When the two are combined, a complete set of “IP armor” is declared formed. IP67, It has become the “gold standard” for many mid to high end robot wheel hub motors – it means that the motor has a “dusty” airtightness and strong resistance to daily splashes and even short-term water immersion.

Why do robots have to wear heavy armor on their ‘feet’?

As the direct driving core of the robot mobile platform, the wheel hub motor integrates the motor, reducer, controller, and brake into one equipment. It is directly exposed to the harshest ‘frontline environment’:

1. Dust invasion: Once a large amount of metal dust from industrial environments, ordinary dust from storage environments, and outdoor sand enters the interior of the motor, it will rapidly accelerate bearing wear, leading to poor coil heat dissipation, overheating damage, or electrical short circuits.

2. Water and Moisture: Cleaning the ground with water stains, outdoor rainwater, and even high humidity condensation in the air are the “natural enemies” of precision electronic components. Mild cases can cause electrical faults, while severe cases can lead to corrosion of permanent magnets and complete scrapping of circuit boards.

3. Reliability is the lifeline: For unmanned robots, any “strike” may cause the entire production line to come to a halt, delivery tasks to fail, or critical inspections to be interrupted. A high-level IP protection that minimizes environmental risks is the cornerstone of ensuring uninterrupted and reliable operation 7×24.

Invisible armor, visible value

Choosing a robot equipped with a high IP level wheel hub motor means putting a ‘hardcore insurance’ on your investment:

In the smart factory, AGV cars can calmly shuttle through the machining workshop, without fear of oil mist and metal shavings, ensuring the stability of logistics lifelines.

In commercial service scenarios, delivery robots can easily cross indoor and outdoor thresholds, effortlessly handling the transition between smooth lobby floors and wet outdoor roads.

In the special field, security inspection robots can protect the safety of the park in wind and rain, and cleaning robots can directly perform water flushing and operations.

This layer of ‘invisible armor’ not only protects the motor itself, but also safeguards the continuity of robot operations and the stability of data collection, ultimately ensuring your operational efficiency and investment return.

Facing the future: stronger ‘feet’ heading towards a wider horizon

With the increasing maturity of robot technology, its application boundaries are rapidly expanding from controlled indoor environments to vast fields of semi outdoor and even fully outdoor environments. From container transportation at port terminals, to field management in smart agriculture, to exploration and rescue in extreme environments, the requirements for environmental adaptability of wheel hub motors are constantly increasing.

This means that IP level will no longer be just a “bonus point”, but will become the core entry threshold for measuring whether robot mobile platforms are truly reliable and capable of handling diverse scenarios. It represents a product design philosophy – setting the most demanding operating conditions as standard configurations and instilling reliability in every detail.

As robots move towards broader horizons, the requirements for the adaptability of wheel hub motors to the environment are constantly increasing. The IP level has evolved from an advantage to a core entry threshold for measuring whether mobile platforms are truly reliable and capable of handling diverse scenarios. It represents a product philosophy that sets strict working conditions as the standard and embeds reliability in every detail.

To put this philosophy into practice and forge the fearless “feet” of robots, it is inseparable from the professional strength of deeply cultivating the industry. For example, Shenzhen Zhongling Technology Co., Ltd. (ZLTECH for short), which is highly recognized in the field of robot power, has always focused on the research and manufacturing of high-performance wheel hub motors. ZLTECH deeply understands the extreme reliability requirements of complex application scenarios, and their wheel hub motor product series is known for its solid sealing technology and rigorous testing, which can provide high-level protection such as IP65, IP67, etc. It is precisely to ensure that the core power unit of the robot can still output stably when facing

Post time: Jan-26-2026