Today, I want to share with you my experience in wheel hub motors. Wheel hub motors are widely used in various fields such as robots and AGVs, including food delivery, cleaning, medical care, and delivery.

I will start with the characteristics and advantages of wheel hub motors, as well as precautions, common problem troubleshooting, and motor selection during use. I hope my sharing can help everyone have a deeper understanding of wheel hub motors and provide some assistance in practical applications;

Characteristics and application scenarios of wheel hub motors:

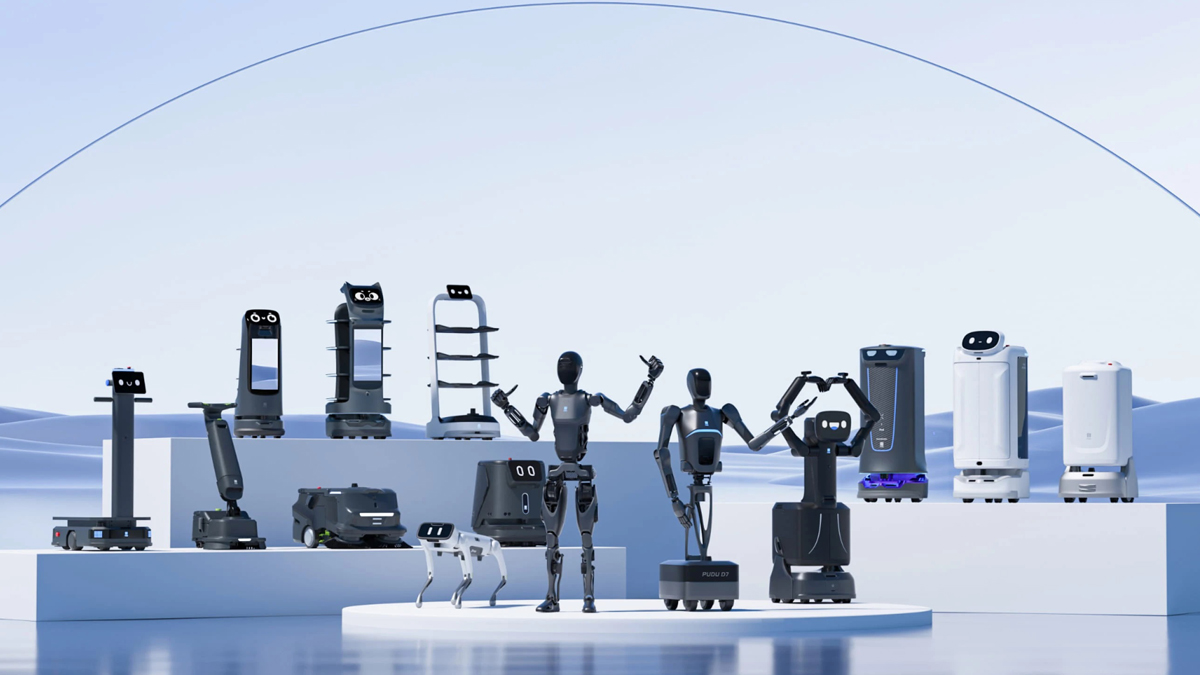

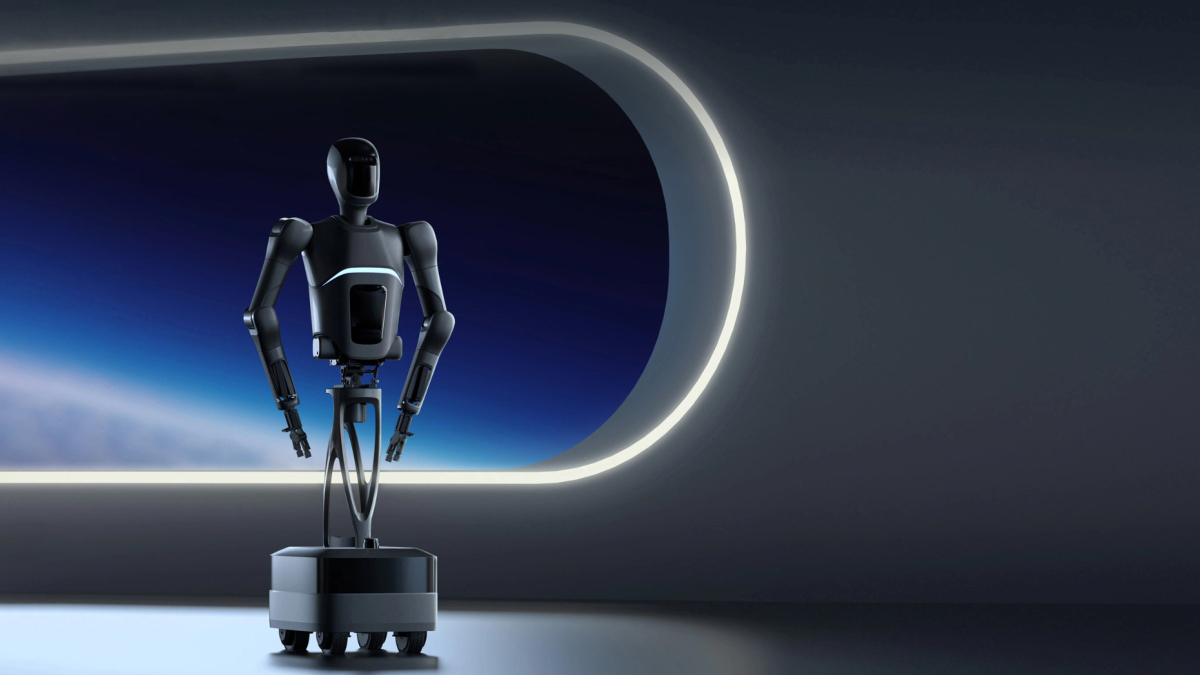

Wheel hub motors have many excellent characteristics, and their high integration means that many functions are integrated into one, reducing the use of external components and making the overall structure more compact and precise. They also have built-in encoders and Hall sensors, which can accurately control the operation of the motor. Fast response allows the motor to quickly respond to control signals, improving work efficiency. Stable low-speed operation ensures smooth operation even at low speeds. In terms of usage environment, wheel hub motors are widely used in various types of robots; Such scenes as meal delivery robots, commercial cleaning robots, building distribution robots, disinfection and sterilization robots, patrol robots, agricultural robots, and small AGVs all need motors with the above characteristics. The hub motor just meets the demand, providing strong support for the stable operation of these devices. The hub motor has many significant advantages.

Advantages of Space Utilization:

On the one hand, it can improve the space utilization of the entire machine, as well as enhance traditional efficiency and effectively save energy losses. This means that in practical applications, it can make equipment operate more efficiently and energy-saving. On the other hand, its driving modes are diverse and can meet the needs of different scenarios. At the same time, wheel hub motors can also reduce the overall design and manufacturing costs, which can effectively control costs for enterprises. The magnetic encoder wheel hub motor has a high protection level and can adapt to more complex environments, ensuring stable operation of the equipment. In addition, its precise control and high dynamic performance can achieve more accurate operations and better performance.

The Importance of Encoder Selection:

When using wheel hub motors, the selection of encoders is also crucial. Optical encoders have a temperature resistance below 65 ° C and a low waterproof and dustproof rating, while magnetic encoders have a temperature resistance of up to 100 ° C and a high waterproof and dustproof rating. Therefore, it is recommended to prioritize the use of magnetic encoders. However, if in a high-intensity magnetic field environment, it is necessary to do a good job in anti-interference protection, and real-time monitoring of the motor’s current and temperature is also indispensable. This can help us timely grasp the actual state of the motor and avoid unexpected situations. In addition, when the robot is charging or resting, it can be put into parking mode, limiting the maximum current to prevent motor overheating and extend the service life of the motor. Motor selection is crucial, and must be based on actual load, voltage, and size. Overloading the motor is absolutely not allowed. You should know that overloading not only affects the performance and lifespan of the motor, but may also cause safety issues.

Precautions for encoder failure:

When users provide feedback on issues such as encoder failure, overcurrent, overheating, and control abnormalities during rapid acceleration and deceleration, we will first understand the methods for controlling acceleration and deceleration. We recommend that the interval time for sending instructions to control the target speed be greater than the acceleration and deceleration time and speed change rate set by the company’s driver, and not too large. For example, if the frequency of the target speed is 10ms, the acceleration and deceleration time should be set to 5ms. At the same time, we recommend setting relevant parameters to control the target speed change rate to 10ms, the acceleration and deceleration time to 5ms, and the speed change rate to 1-3 RPM. This can avoid problems during rapid acceleration and deceleration of the motor.

In the previous content, we delved into the various aspects of wheel hub motors and their advantages, such as improving space utilization, energy conservation, and consumption reduction. We also discussed the key points of motor selection, such as selecting encoders and monitoring motor status. We provided solutions to the problems encountered by customers during use, such as rapid acceleration and deceleration, continuous obstacle crossing, etc. We hope that these contents can provide valuable references for everyone.

Shenzhen Zhongling Technology Co., Ltd. is a comprehensive motor+drive motion control solution company. Stepper motors, servo motors, and drives have been widely used in mechanical equipment in various industries and continuously researched and innovated. It has successively launched wheel hub motors and integrated stepper motors. Its wheel hub motors have deep cooperation with major robot companies and have been widely applied and promoted in restaurants, factories, and other places. In this era of rapid technological development, only continuous innovation can avoid being swallowed up by the future. Zhongling Technology has launched a variety of new motors and drives ZLAC8015, which can be seen on the official website for details https://www.robotmotor.com/

Post time: Dec-09-2025